Imagine walking into a fast food restaurant and placing an order for a burger and fries… The Wagyu beef for your burger is immediately fresh-ground, formed into a patty, cooked to the perfect internal temperature. At the same time, a fresh basket of fries is dropped into a fryer and, at the precise second when they are perfectly cooked, lifted and dropped into a container for serving.

You might think such precision and quality would be unattainable with the often inexperienced, high-turnover staff at a typical fast food restaurant. But at CaliExpress by Flippy in Pasadena that’s not a problem. Both the burger preparation and fry cooking are done by robots made by Miso Robotics. “Flippy” is a robotic arm and sensor system that cooks the fries, while the burgers are crafted by “BurgerBot.”

Miso calls the Pasadena location the world’s first “fully autonomous restaurant.”

Order with your face

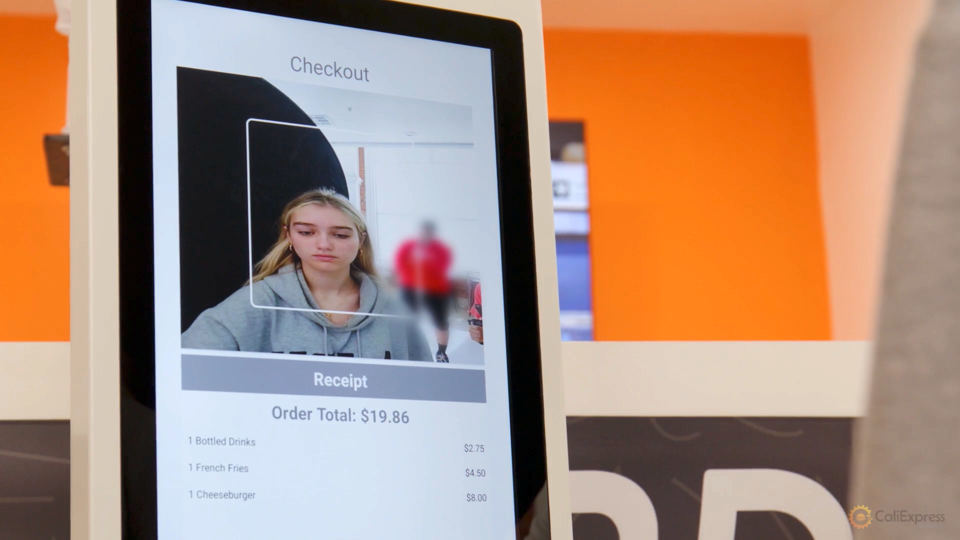

Highly automated food preparation isn’t the only innovation being demonstrated at CaliExpress. The restaurant has also implemented PopID stations for ordering and payment. Customers can set up a profile with their face, payment method, and loyalty info. Once set up, a customer can place orders, pay, and earn loyalty points without credit cards, loyalty cards or a smartphone.

PopID facial recognition lets repeat customers pay without credit cards, loyalty cards, or a … [+]

To further speed the ordering process, a customer can quickly select a previous order on subsequent visits.

PopID appears to be pursuing the same market for biometric authentication as Amazon One, CLEAR, and others.

Lower Cost, Better Safety

Fast food workers have been in short supply in many locations, even as the minimum wage at chain locations will rise to $20 per hour in 2024. Miso says labor cost savings from automation are what enables the restaurant to serve the more expensive Wagyu beef in their burgers.

Miso’s “Flippy” robot keeps humans way from hot oil and slippery surfaces

In addition to cutting labor costs, Miso says the robots will keep human workers safer by not placing them next to potential dangers like high temperature cooking oil and slippery surfaces near fryers.

Humans Still Needed

The term “autonomous” may apply to the the food ordering and cooking steps, but human workers will still “assemble” the burgers and package them for handing off to customers. Presumably, the human workers will be available to assist customers in ordering and watch for any issues with the automation.

Being separated from hot oil and dangerous surfaces might also improve worker retention. Annual fast food worker turnover can run as high as 150%. Anything that reduces the cost of hiring and training new workers would be welcomed by restaurant operators.

CaliExpress Opening “Soon”

At press time, CaliExpress in Pasadena isn’t open to the public. The expected opening date was December of this year, and a spokesperson confirms it will be “opening soon.” The firm hopes to prove the concept in 2024 with its current location and then open additional stores.

The real business opportunity is not selling Wagyu burgers. Rather, it’s to sell automation technology to other chains. There are nearly 200,000 fast food restaurants in the U.S. alone, with over 800,000 globally.

Cali Group is a holding company that owns both Miso and PopID along with the CaliBurger brand. Surely their focus is on the vast equipment market in fast food and beyond.